Locksmithing is a trade that relies heavily on the quality and condition of your tools. Without well-maintained equipment, even the most skilled locksmith will struggle to deliver efficient and effective service. In this comprehensive guide, we’ll explore essential tips and techniques for keeping your locksmith tools in perfect condition. Whether you’re a seasoned professional or an apprentice just starting out, these guidelines will help ensure your tools remain reliable and long-lasting.

Maintaining your locksmith tools is not only about prolonging their lifespan but also about ensuring the precision and effectiveness of your work. Poorly maintained tools can lead to inaccurate results, increased risk of injury, and higher replacement costs. In this article, we will cover various aspects of tool maintenance, from cleaning and storage to sharpening and calibration. By following these practices, you can maximize the efficiency and durability of your locksmith tools.

The Importance of Regular Maintenance

Preventing Wear and Tear

Regular maintenance is crucial to prevent wear and tear on your tools. Over time, dirt, debris, and rust can accumulate, leading to corrosion and reduced functionality. By incorporating routine cleaning and maintenance into your workflow, you can prevent these issues and keep your tools in optimal condition.

Enhancing Precision

Locksmithing requires precision and accuracy. Tools that are well-maintained are more likely to perform accurately, ensuring that locks are opened, repaired, or replaced without causing damage. Regular sharpening and calibration of tools are essential for maintaining this level of precision.

Safety Considerations

Using poorly maintained tools can pose significant safety risks. Blunt or damaged tools can slip, causing injury to the user or damage to the lock. Regular inspection and maintenance of your tools help mitigate these risks, creating a safer working environment.

Cleaning Your Locksmith Tools

Daily Cleaning Routine

Developing a daily cleaning routine is the first step in maintaining your locksmith tools. After each use, wipe down your tools with a clean, dry cloth to remove any dust or debris. For more thorough cleaning, use a soft brush to remove dirt from hard-to-reach areas.

Deep Cleaning Techniques

For tools that require a deeper clean, consider using a mild detergent and warm water. Submerge the tools in the soapy water, scrub gently with a soft brush, and rinse thoroughly. Be sure to dry the tools completely to prevent rust formation. For stubborn grime, a mixture of vinegar and water can be effective.

Rust Prevention

Rust is a common enemy of metal tools. To prevent rust, store your tools in a dry environment and consider using a rust inhibitor or lubricant. Regularly applying a light coat of oil to your metal tools can also help prevent rust and corrosion.

Sharpening and Calibration

Sharpening Blades and Edges

Sharp blades and edges are essential for the effective functioning of many locksmith tools. Regularly inspect your tools for signs of dullness and sharpen them as needed. Use a sharpening stone or a fine-grit sandpaper to restore the sharpness of your blades. Be sure to follow the manufacturer’s instructions for the correct angle and technique.

Calibrating Measuring Tools

Precision measuring tools, such as calipers and micrometers, require regular calibration to ensure accuracy. Follow the manufacturer’s guidelines for calibrating these tools, and consider having them professionally calibrated at regular intervals. This practice ensures that your measurements remain accurate and reliable.

Proper Storage Solutions

Organizing Your Workspace

An organized workspace is essential for maintaining your tools. Invest in a quality tool chest or cabinet to keep your tools neatly stored and easily accessible. Use foam inserts or custom compartments to prevent tools from moving around and getting damaged.

Climate-Controlled Storage

Environmental factors, such as humidity and temperature, can affect the condition of your tools. If possible, store your tools in a climate-controlled environment to prevent rust and other damage caused by extreme conditions. Dehumidifiers and silica gel packs can help control moisture levels in your storage area.

Tool Cases and Bags

For locksmiths who frequently work on-site, a durable tool case or bag is essential. Choose a case with padded compartments to protect your tools during transport. Look for features such as reinforced handles and zippers to ensure longevity.

Specialized Maintenance Tips

Caring for Lock Picks

Lock picks are delicate tools that require careful maintenance. Inspect your lock picks regularly for signs of bending or wear. Use fine-grit sandpaper to smooth out any rough edges, and store your picks in a protective case to prevent damage.

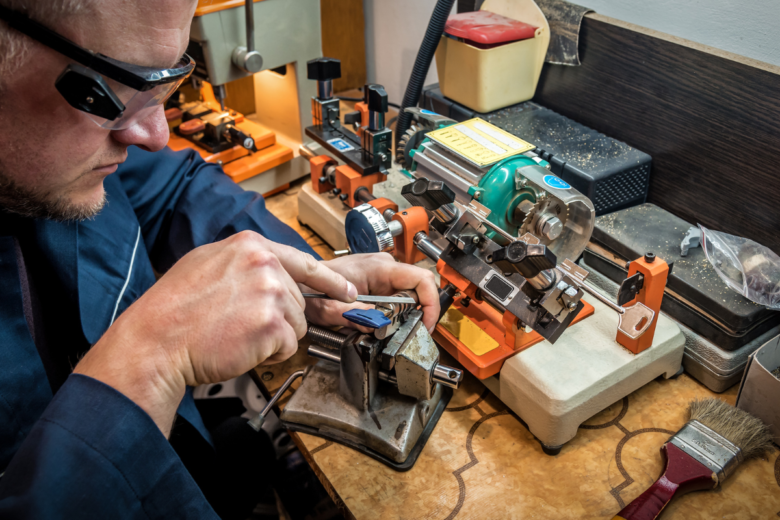

Maintaining Key Cutting Machines

Key cutting machines are an investment that requires regular maintenance. Follow the manufacturer’s maintenance schedule, which may include cleaning the machine, lubricating moving parts, and checking for alignment issues. Replace worn or damaged cutting wheels promptly to ensure precise key cutting.

Servicing Tension Wrenches

Tension wrenches are essential for lock picking and should be inspected regularly for signs of wear. Replace any wrenches that show signs of bending or damage. Store tension wrenches in a case or compartment to prevent them from getting lost or damaged.

Advanced Tool Care Techniques

Using Ultrasonic Cleaners

For a thorough and efficient cleaning, consider using an ultrasonic cleaner. These devices use high-frequency sound waves to remove dirt and grime from your tools. Ultrasonic cleaners are especially effective for cleaning small, intricate tools that are difficult to clean manually.

Applying Protective Coatings

Applying protective coatings to your tools can enhance their durability. Consider using a tool-specific coating, such as a rust inhibitor or a polymer coating, to provide an additional layer of protection against wear and corrosion.

Implementing a Maintenance Schedule

Creating a maintenance schedule can help ensure that all your tools receive regular care. Schedule time for daily, weekly, and monthly maintenance tasks, and keep a log of your activities. This proactive approach can prevent issues before they arise and extend the lifespan of your tools.

Troubleshooting Common Issues

Identifying Signs of Wear

Regularly inspect your tools for signs of wear, such as rust, dullness, or damage. Early identification of these issues allows for timely repairs or replacements, preventing further damage and ensuring your tools remain effective.

Addressing Tool Malfunctions

If a tool malfunctions, stop using it immediately and inspect it for the cause of the issue. Common causes of malfunctions include dirt buildup, worn parts, or misalignment. Clean the tool thoroughly, replace any damaged components, and recalibrate if necessary. If the problem persists, consider consulting a professional for repair or replacement.

Dealing with Rust and Corrosion

If you discover rust or corrosion on your tools, address it promptly to prevent further damage. Use a rust remover or a mixture of vinegar and baking soda to clean the affected area. Scrub gently with a wire brush or steel wool, rinse thoroughly, and dry completely. Apply a light coat of oil to prevent future rust formation.

Maintaining your locksmith tools is an ongoing process that requires dedication and attention to detail. By implementing regular cleaning routines, sharpening and calibrating your tools, and investing in proper storage solutions, you can ensure that your tools remain in perfect condition. Advanced techniques, such as using ultrasonic cleaners and protective coatings, can further enhance the longevity and performance of your equipment.

Remember, well-maintained tools are essential for delivering precise, efficient, and safe locksmithing services. By prioritizing tool maintenance, you not only protect your investment but also enhance the quality of your work and the satisfaction of your clients. Follow the tips and techniques outlined in this guide, and your locksmith tools will remain reliable and effective for years to come.

I’m Marcel Brandt, a locksmith with over 15 years of experience. I specialize in modern security solutions and love sharing tips to help fellow locksmiths succeed in their careers.